No Dig Drain Relining

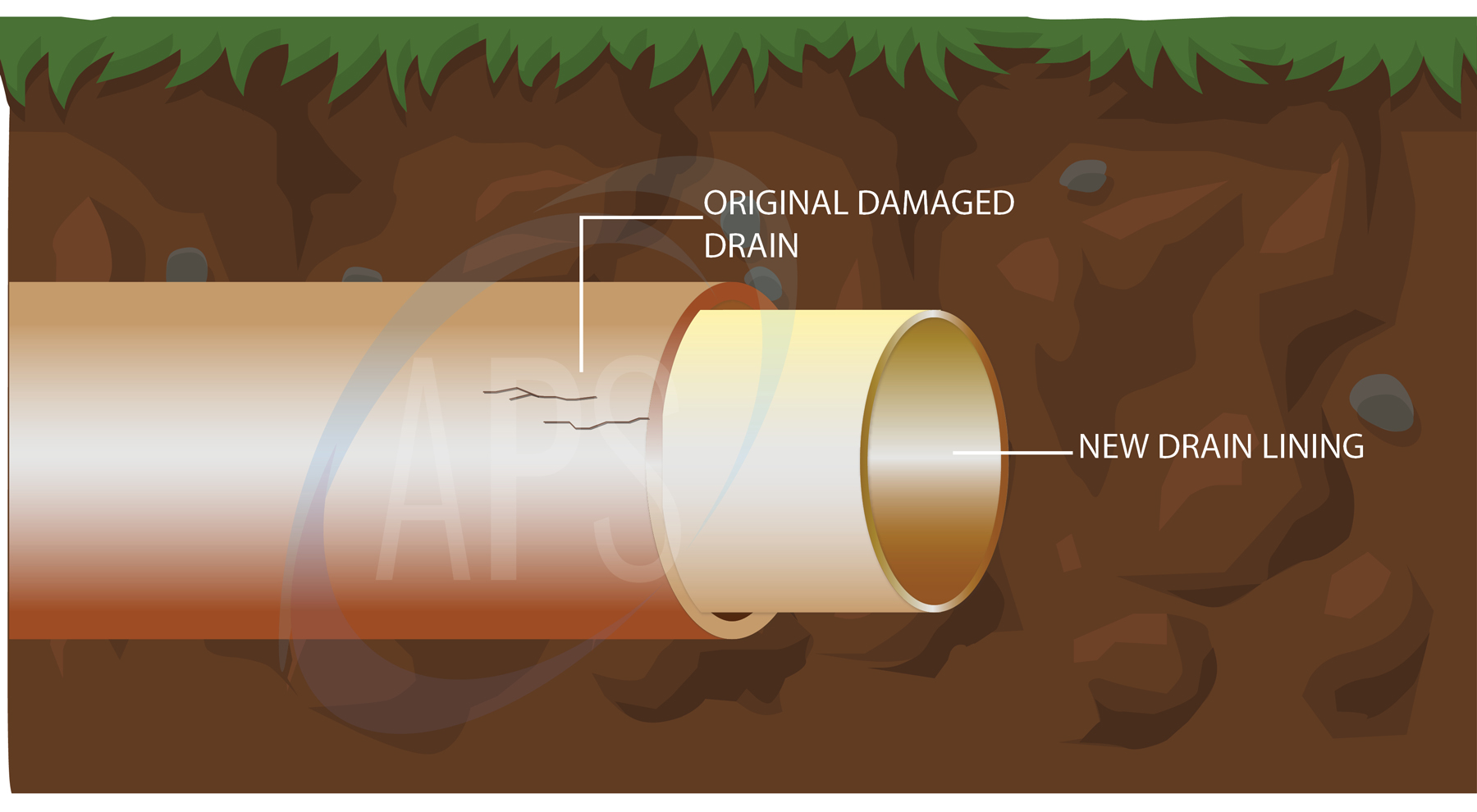

Our drain relining service can repair cracked or damaged drains without the need for excavation.

Drain lining is a cost-effective and non-invasive alternative to excavating and replacing damaged drains. With drain lining there is minimal disruption to your premises or property. We can carry out a CCTV drain survey to identify the cause of the issue and carry out structural drain lining to effectively repair the damage. Our professional team re-line cracked drain pipes avoiding the need for excavation.

Drain lining, or ‘No dig’ technology, allows us to repair damaged drains, without having to excavate or dig a trench. Pipes are repaired by lining the existing drain pipe. Drain lining is a quicker, cleaner and less disruptive solution to drain repairs.

Structural Drain Lining

This type of lining is joint-free, which significantly reduces the chance of root intrusion. This process can be undertaken with minimal fuss or disruption to your home, school, club or workplace.

HOW DOES DRAIN LINING WORK?

A resin drain lining or ‘drain sleeve’ is inserted into the damaged drain which is bonded to the surface. This creates a newly sealed surface inside the drain pipe allowing liquids to flow freely again.

Drain relining is often used to repair leaking pipes and circumferential or radial cracks caused by blockage damage. In older drainage systems clay pipes are prone to damage by root ingress – drain lining is an effective method to remedy this problem.

WHAT IS THE PROCESS OF DRAIN LINING ?

Inspection

If you have observed signs of a broken or damaged drain our team will carry out an inspection. Using CCTV survey equipment they will identify and locate the affected area.

Remove obstructions

Once the damaged drain has been located the team will clear any obstructions. This includes debris, scale build up, grease deposits and tree roots. This can include the process of rodding and high pressure drain jetting.

Re-inspection

Our team make a final inspection to ensure all obstacles are removed and that the drain is prepared for lining.

Installation

Inversion lining is a cost effective method of relining a damaged drain. Resin is poured into the drain liner and rolled to ensure it is evenly distributed. An inversion drum facilitates the installation of the flexible resin impregnated pipe lining into the damaged drain. During the process, the resin-saturated lining is inverted and pressed against the pipe’s inner walls to form a bond.

Curing

Cured-In-Place Pipe (CIPP) lining requires a heating source (water or steam) that runs through the pipe and liner to cure the resin to form a permanent bond between the pipe and the liner.

DRAIN EXCAVATIONS

Drain Replacement

CCTV DRAIN INSPECTION

ADVANTAGES OF DRAIN LINING

- Reduced repair costs

- Minimal disruption

- Speed of repairs

- Structural integrity

- Prevention of root ingress

CAUSES OF A BROKEN OR CRACKED DRAIN

- Unstable ground (earth movement, construction)

- Inner (water) & Outer (ground) pressure changes

- Extreme temperature changes (ground freezing/thawing)

- Tree roots infiltrating sewer pipe holes / joints

- Scale Build Up

- Mis-connection

- Wear & Tear

- Corrosion

HOW WE CAN HELP

No dig drain relining allows us to repair the interior of your drain without the need for excavation. Our operations team will discuss with you the best time to implement the repair ensuring minimal inconvenience for the fastest and most cost-effective way to repair a damaged drain.

Why Choose Alton Pump Services?

EXPERIENCED ENGINEERS

REPUTATION FOR QUALITY

24/7 CALL OUT

What our clients have to say

This company works for us on a regular basis, we have many projects on the go all the time and whenever we have drainage issues we call in Alton Pumps. They were recommended to us by one of our clients, Surrey County Council, and we bought them on-board as a specialist sub contractor.

CUSTOMER, BASILDON

Treatment Plant problems – Called Alton Pump Services because our treatment plant went into alarm, Alton Pump Services attended very quickly and diagnosed the fault. They fixed the problem and arranged a tanker for the emptying. Overall very happy with the service we received. Recommended Company.

CUSTOMER, GODALMING

New pumps installed in septic tank. 2 professionals came and undertook a complex, dirty and stressful job with ease. They were transparent, reassuring and professional and they went above and beyond the call of duty to get my problem fixed. I’d recommend them again. they’re worth every penny.