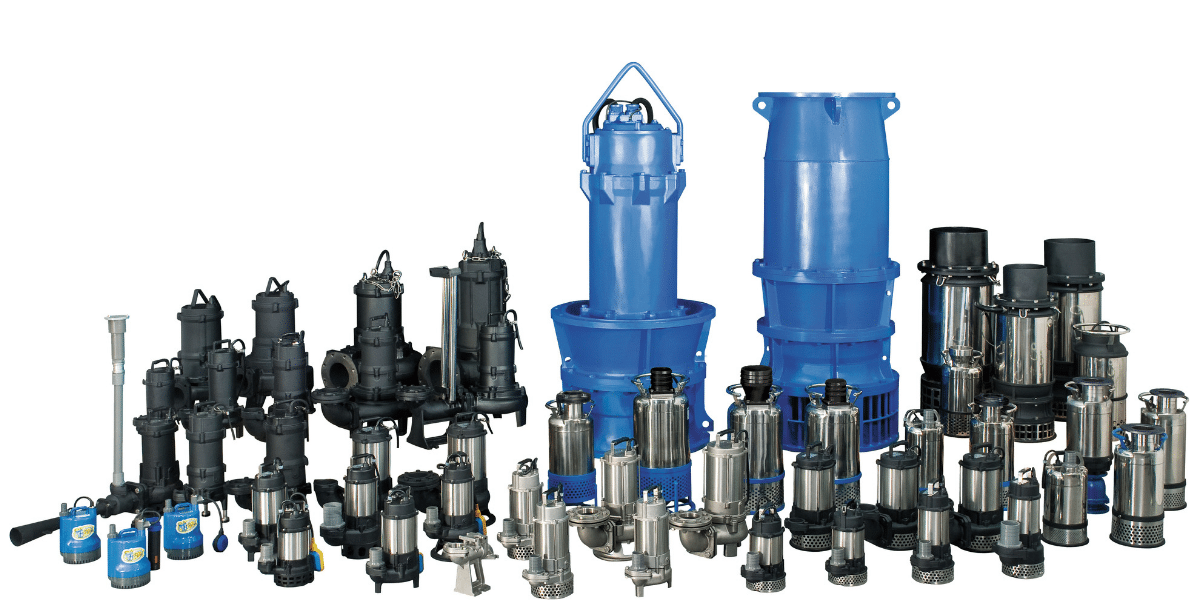

HCP Pumps

At Alton Pumps Services we have over 300 HCP pumps in stock including:

Sewage Pumps

Guide Rail Pump Systems

Large Volume Series

Submersible Dewatering Pump

Residential Sump Pump

Construction Submersible Dewatering Pump

Waste Water Pumps

Grinder Pumps

General Watse Water Pumps

The full range of HCP pumps cover a wide variety of applications such as:

Drainage of waste water containing fibrous additives from leather factory, including both dyeing and food processing factories. Also, sewage management, accumulated water, and septic tanks. In addition to pumping sewage from hotels, restaurants, schools and public buildings. And also providing water supply for agricultural irrigation systems and underground water pumping. Plus, landscape, water feature and horticulture irrigation. Finally, extraction of water from rivers, lakes and reservoirs.

HCP Pumps are ISO 9001 certificated. Research and development are the driving force behind product information. All parts and materials used in the manufacturing of HCP products meet high quality assurance standards before moving to the production line for assembly.

AF TYPE SEWAGE PUMPS

FEATURES:

- International standard design: VCT and 2PNCT cable, auto-cut, dry-motor, silicon carbide mechanical seal, coupled with high grade cast iron. This results in good quality and performance.

- Also P/U/E multiple impellers design to handle sewage containing both large solid and fibre substance.

- Including strong abrasion resistant mechanical seal made of silicon carbide to ensures the best seal effect.

- We installed oil-seal rings under the oil chamber for extra protection. This lip seal helps to prevent both silt and sand to get into the lower seal.

- In addition we have a full range from low head to high head, compact and easy installation. Available with TOS system which makes it easy to automatically connect and disconnect from above the pits by means of guide rail system.

- Finally a 100% non-clogging impeller design.

AUTO CUT:

- Equipped with automatic reset motor protector. Subsequently preventing the motor from burning due high temperature/open phase/voltage drop and lock impeller.

CABLE BASE:

- We use an epoxy resin seal cable base to prevent water intruding into the motor through the core wire.

APPLICATIONS:

- Drainage of waste water from the liberation tank, purifying tank and sewage tank in water treatment plant.

- Drainage of waste water and inclusion containing fibrous admixtures from leather factories, dyeing factories and food processing factories.

- Sewage management, accumulated water, septic tank, stock farm.

- Futhermore, pumping sewage from both single and multifamily dwellings, plus

- Finally, pumping sewage from hotels, restaurants, schools and public buildings.

P type impellers

Semi-open impeller embedded with a tungsten blade. This cuts fibrous materials to prevent clogging.

U type impellers

Vortex impellers is create a hydraulic passage. This allows long fibrous material pass without any contact with the impeller. Thus preventing potential clogging by solid media.

E type impellers

Channel impeller-Effective for drainage and higher dead generation with liquids containing solids.

AF TYPE HEAVY DUTY SEWAGE PUMPS

FEATURES:

COATING

At HCP we coat the surface of our pumps with thick and solid Epoxy paint to provide a better surface protection and corrosion resistance.

CABLE BASE

We isolate each cable base with hardened epoxy sealing treatment to prevent water seeping into motor through the core wire.

BEARING

We used heavy duty and high quality bearing to ensure long-term operation. We designed our bearing to meet the specification of dimension, basic load ration, and bearing environment.

WD water-detector

An optional mechanical seal leakage detector will send a signal to the control panel when water infiltrates. The use of the leakage detector prevents water from entering the motor chamber in case of mechanical seal failure.

ELECTRIC MOTOR

Dry type, high efficiency copper wound motors with F class insulation. The motors are produced under strict quality control procedure. The stator winding is impregnated with vanish resin and keep in the oven for cure up to 8 hours in whole process.

MTP-Miniature Thermal Protector

Miniature Thermal Protector is embedded in the windings of the motor. MTP will transmit a signal to circuit broad during temperature of the windings increases to acting point. An external motor protection circuit is activated to protect motor from over heating.

Mechanical seals

Equipped with extremely hard faces hard silicon carbide double mechanical seals for wear-resisting. Consequently providing the best lubricity to prolong usage.

Impeller

Our E type, non-clog single channel impeller design with 3 inch solid passage and prevents clogging to solve all dewatering problems.

HIGH EFFICIENCY IMPELLER INVESTIGATION

We utilize computerized engineering for assisting analysis of impeller performance, and 3D impeller design techniques to upgrade the precision and reduce designing period.

F TYPE GENERAL SEWAGE PUMPS

Features:

- A precision manufactured motor is achieved utilizing a laminated sheet steel production process combined with the highest standard of quality control. The drive shaft and rotor assembly is heat-treated. We varnish and then heat dry in an industrial oven the stator and wiring. This ensures a motor with stable characteristics and high efficiency.

- HCP Pumps professional production assembly line, complimented with a synthesized production test ensures the highest level of final pump quality.

- Standard accessories include: VCT cable with an epoxy resin sealed water-resistant cable base. Also AC thermal motor protector, dual mechanical seal and lip seal design.

- Equally important, our U type Vortex Non-clogging impeller or P type Semi-open cutter impeller design, deals with with any wastewater or sewage application with the best dewatering efficiency.

- Automatic float switch control is available for both 0.5 and 1.0HP single phase powered pumps.

- We designed our full product line range with both high impact resistance and to be light weight. This results in simple transportation.

- The smallest pump in the range is the F-05A. This is an extremely practical pump, has a both a low temperature oil filled motor and single seal design.

To summarize, suitable applications are:

To drain sewage from the building basements, including the hotel industry, waste water from factories. Also, draining of sewage from industrial process factories. Plus emptying of both septic tanks and cesspits, and also sewage pump stations. In addition to pump surface and drainage water from garages and sprinkler systems.